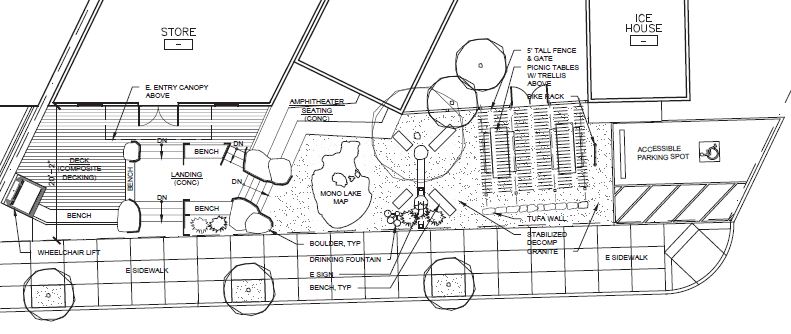

The Mono Lake Committee’s current storefront remodel project is an exercise in planning, engineering, construction, and … art. Right in there with the deck, shade structures, greywater system, steps, lights, picnic tables, water fountain, and boulders, there is a spot dedicated to what will soon be a ten-foot by ten-foot map of Mono Lake inlaid into the concrete.

In early conversations with the architects the idea for using the outline of the lake in the plans materialized when looking at the space we had available, and it quickly became a signature feature.

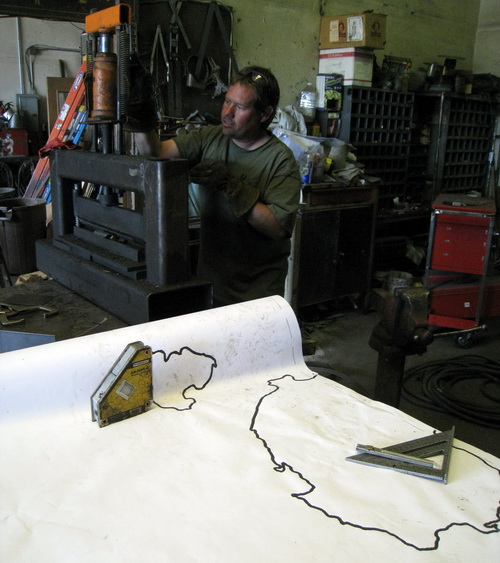

Years later, with the asphalt torn up, it’s time to turn the idea into reality. Roy of Escoto Construction & Design has taken extra special care to make sure the map is done right—which means enlisting creative contractors who are willing to think, and work, outside of the box. After Committee Information & Restoration Specialist Greg Reis checked the outline of the map for accuracy, the contractors began working their magic.

This afternoon I got to see the two local welders, Scott and Dale from PDG Welding in Mammoth Lakes, creating the metal forms that will contain the concrete that will make up the Mono Lake map.

The Negit Island outline is the most complex piece, and took six hours of welding. When I left Scott and Dale were working on the outline of Paoha Island and the south shore of the lake. Once they have the pieces shaped they’ll weld the whole thing together, complete with the structural pieces necessary to make the concrete pouring work, and we’ll be into the concrete phase. We’ll keep you posted on the progress.